Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

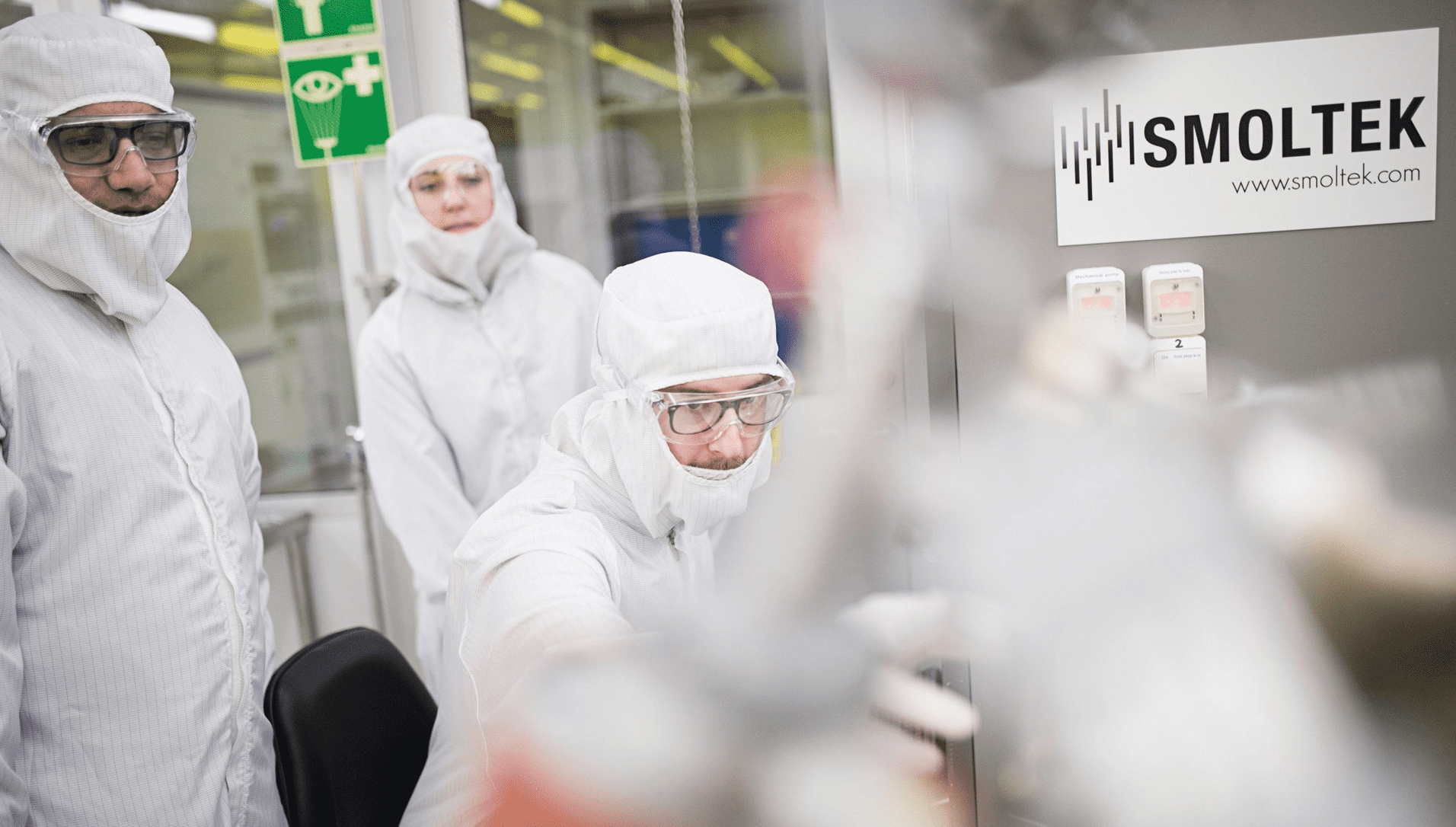

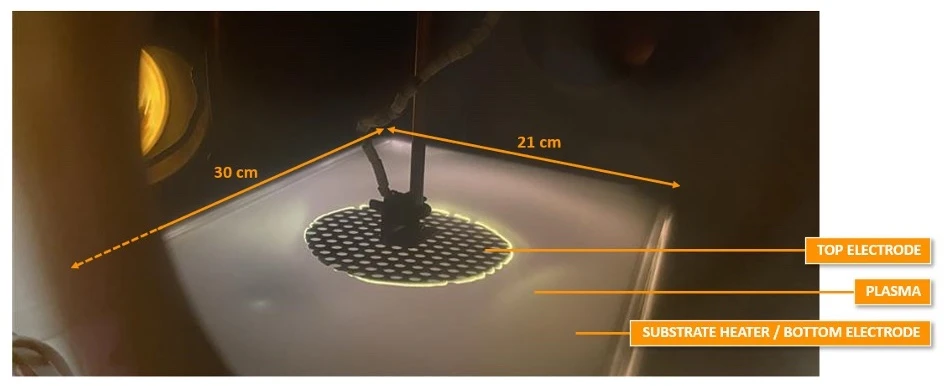

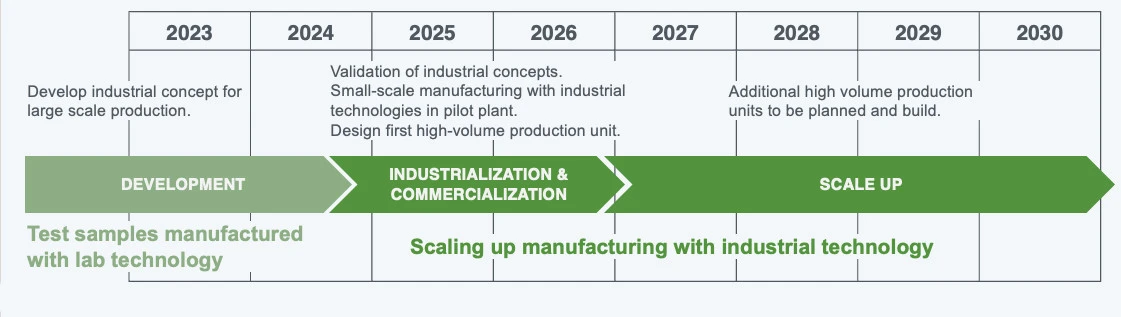

Towards scalability of industrial carbon nanofiber growth: The development of the industrial manufacturing concept for Smoltek Hydrogen’s Electrolyzer Cell Material is at its final stages, with aim on being finalized during 2024. As a stepping stone, the capability in the company’s existing Plasma Enhanced Chemical Vapor Deposition (PECVD) tool has been extended and A4 size plasma has been achieved. This is a crucial step towards industrial scalability of carbon nanofiber growth.

Smoltek Hydrogen has successfully refurbished the in-house developed proprietary PECVD R&D tool, from its 6‑inch diameter area, to be compatible with A4 size. This corresponds to an expansion of area by more than 3 times, and stable plasma covering the entire A4 area has been achieved.

By expanding our capabilities in the R&D tool we gain useful knowledge that will prepare and speed up the transfer of the growth recipes from laboratory technology in the R&D tool to industrial technology in the Prototype Coater* , why achieving A4 size plasma is an important stepping stone towards a scalable industrial process.

Shafiq Kabir, Head of Volume Processes at Smoltek Hydrogen

Currently Smoltek’s PTE cell material prototypes are manufactured with laboratory technologies, and the carbon nanofibers are grown using the R&D PECVD tool which up until now has been capable of coating up to approximately 6‑inch diameter area. Electrolyzer cells and their constituent materials are often rectangular or square shaped and electrolysis test systems are typically designed for square shaped prototypes, so is the test system used by Smoltek Hydrogen, why it is more suitable to adapt the tools for rectangular or square shaped instead of round ones. A larger rectangular shape also provides higher flexibility by being able to produce both single large prototype or a higher quantity of multiple small ones during a single run, which in turn enables faster development and increased capacity to provide prototypes to customers based on their size needs.

Plasma – fundamental for carbon nanofiber growth

Plasma is one of the four fundamental states of matter, alongside solid, liquid, and gas, and it is characterized by the electrons being separated from their parent atoms or molecules, which simplified means that plasma is a cloud of electrons and a source of extra energy in the system. Plasma has unique properties and achieving a stable plasma is essential for Smoltek’s process of carbon nanofiber growth on the porous transport layer (PTL) for its electrolyzer cell material.

The successful rebuild of the in-house PECVD R&D tool to A4 size plasma is an initial result at one of our growth recipes, and the focus now is to further improve and fine-tune the hardware and recipe, and validation by growing nanofibers on PTLs.

Shafiq Kabir, Head of Volume Processes at Smoltek Hydrogen

* Smoltek Hydrogen has finalized design of a prototype coater

Fact box: Smoltek Hydrogen’s PTE cell material:

Smoltek Hydrogen is developing a nanofiber based porous transport electrode (PTE) cell material for the anode in PEM electrolyzers. The cell material consists of a sintered porous titanium layer (PTL) where the surface area has been enhanced with vertical nanofibers, a conformal platinum corrosion protection and ultra-thin nanoparticle layer of iridium catalyst. The material is one of the layers in an electrolyzer cell. When manufacturing electrolyzers, a large number of electrolyzer cells are assembled into a cell stack, which is the main element in the electrolyzer as it is where the electrolysis takes place and hydrogen is produced.

Your data will be handled in compliance with our privacy policy.

News

June 12, 2025

Smoltek Hydrogen is developing Smoltek PTE – a proprietary porous transport electrode based on carbon nanostructures, which is intended to meet the requirements of next-generation PEM electrolyzers for the production of fossil-free hydrogen.

News

May 20, 2025

Smoltek has been awarded a new patent within the hydrogen business area. The patent discloses a method for depositing conformally coated catalyst support for the PTL (porous transport layer) that provides both high catalytic activity and additional corrosion protection.